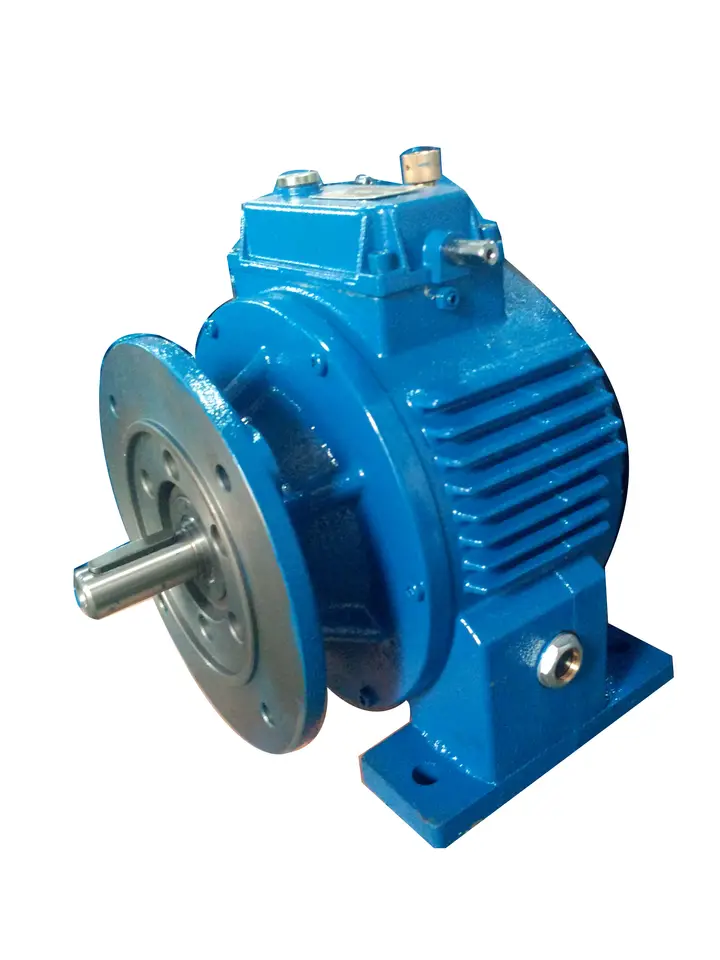

Product Description

P Series Planetary Gearbox/ Planetary Gear Box/ Speed Reducer

Product Parameters

|

Product Name |

Best price of P series planetary gearbox for concrete mixer |

|

Series |

gear reducer |

|

Application |

Power Tranmission |

|

Bearing |

China Top brand HRB,LYC,ZWZ or other brands requested, CHINAMFG |

|

Used |

industry machinery |

Product Description

1.P series planetary gear reducer is widely used in metallurgy , mining, lifting and transport , electricity, energy , building

materials, light industry, transportation and other industrial sectors.

2. P series planetary gear involute planetary gear transmission , within a reasonable use, external gear , power split .

3. The planetary gear modular design changes can be combined according to customer requirements.

4.Carburized gears are used to obtain high- hard wear-resistant surface , all the heat treatment after grinding gear teeth ,

reduce noise , improve the overall efficiency and service life.

5. Hight quality gear reducer , small transmission ratio range , high efficiency, smooth operation, low noise adaptability and

other characteristics .

1.We manufacture and sell HB,XB,P, F, S,K,R series speed retarders and transmissions. 2.A variety of models are available. You are welcome to inquire.

3.We offer certifications:CO/PVOC/ FERI/SUNCAP/ISO 9001:2008

4.OEM service :logo,lable ,manual ,and packages

Detailed Photos

Our Advantages

Company Profile

Certifications

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100000/Piece

1 Piece(Min.Order) | |

|---|

How do variator gearboxes contribute to optimizing the efficiency of conveyor systems?

Variator gearboxes play a crucial role in optimizing the efficiency of conveyor systems. They offer several advantages that contribute to improved performance, energy efficiency, and overall productivity. Here’s how variator gearboxes help optimize the efficiency of conveyor systems:

- Variable Speed Control: Variator gearboxes enable precise and continuous adjustment of the conveyor’s speed. This variable speed control allows operators to match the conveyor’s speed to the specific requirements of the material being transported or the production process. By running the conveyor at the optimal speed, energy wastage is minimized, and the system operates more efficiently.

- Load Adaptability: Conveyor systems often handle varying loads or different types of materials. Variator gearboxes offer load adaptability, allowing the conveyor to adjust its speed and torque output based on the applied load. This adaptability ensures that the conveyor operates at the appropriate power level, minimizing energy waste during periods of low load or when handling lighter materials.

- Smooth Starting and Stopping: Variator gearboxes provide smooth acceleration and deceleration capabilities, allowing the conveyor to start and stop gradually. This feature reduces stress on the conveyor components, minimizes jerky movements, and prevents material spillage. Smooth starting and stopping also contribute to energy efficiency by reducing power surges and mechanical stress on the system.

- Optimized Power Transmission: Variator gearboxes are designed to optimize power transmission efficiency. They utilize efficient power transfer mechanisms, such as belts or chains, along with well-engineered pulley systems. These systems minimize power losses due to friction and slippage, ensuring that a greater percentage of input power is effectively delivered to the conveyor belt, reducing power consumption.

- Customizable Gear Ratios: Variator gearboxes offer a wide range of gear ratios that can be adjusted based on the specific conveyor requirements. By selecting the optimal gear ratio, the variator gearbox ensures efficient power transfer and reduced power losses. The customizable gear ratios allow the conveyor to operate at the most favorable speed and torque combination, maximizing energy efficiency.

- Integrated Control Systems: Variator gearboxes can be integrated with advanced control systems and automation technologies. These systems enable precise control over the conveyor’s speed, acceleration, and deceleration profiles. By implementing intelligent control algorithms, variator gearboxes can optimize the conveyor’s operation based on real-time production demands, minimizing power consumption and maximizing productivity.

- Maintenance and Serviceability: Variator gearboxes often offer ease of maintenance and serviceability features. They may incorporate features like quick belt tension adjustment mechanisms, easy access to components for inspection and maintenance, and built-in condition monitoring systems. These features simplify maintenance tasks, reduce downtime, and ensure that the gearbox operates at its peak efficiency.

By leveraging the variable speed control, load adaptability, smooth starting and stopping, optimized power transmission, customizable gear ratios, integrated control systems, and maintenance features, variator gearboxes contribute to the overall optimization of conveyor system efficiency. They enable energy-efficient operation, reduce power consumption, enhance material handling capabilities, and improve the productivity and reliability of conveyor systems in various industries.

Can variator gearboxes be customized for specific speed and torque ranges?

Yes, variator gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer the flexibility to design and configure variator gearboxes according to the specific needs of customers. Here’s how variator gearboxes can be customized for specific speed and torque ranges:

Variable Pulley Design:

The design of the variable pulley system in a variator gearbox can be customized to achieve desired speed and torque ranges. The shape, size, and configuration of the pulleys can be adjusted to provide different gear ratios and accommodate specific application requirements. By modifying the pulley’s dimensions and angles, variator gearboxes can achieve a wide range of speed ratios and corresponding torque outputs, allowing customization for specific speed and torque ranges.

Selection of Components:

Manufacturers can select and optimize various components within the variator gearbox to match specific speed and torque ranges. This includes the choice of materials for gears, bearings, and other critical components. By selecting appropriate materials, manufacturers can ensure that the variator gearbox can handle the required torque levels without compromising its durability and performance.

Torque-Sensing and Control Systems:

The torque-sensing and control systems within variator gearboxes can be customized to provide precise control over speed and torque. Manufacturers can incorporate sensors and control algorithms that are tailored to the specific speed and torque requirements of an application. These systems monitor the torque load and adjust the gear ratio accordingly to maintain the desired speed and torque output, allowing for customization within specific ranges.

Applications in Parallel or Series:

In some cases, multiple variator gearboxes can be configured in parallel or series to achieve the desired speed and torque ranges. By combining the outputs of multiple variator gearboxes, either in parallel or series arrangement, the overall speed and torque capabilities can be customized to meet specific application requirements. This configuration allows for scalability and adaptability to different speed and torque demands.

Computer-Aided Design (CAD) and Simulation:

Manufacturers utilize computer-aided design (CAD) software and simulations to customize variator gearboxes for specific speed and torque ranges. CAD tools enable the design and optimization of components, ensuring they can withstand the required torque levels and operate within the desired speed ranges. Simulations help manufacturers evaluate the performance of the customized variator gearbox under different operating conditions, allowing for fine-tuning and optimization.

Collaboration with Customers:

Manufacturers work closely with customers to understand their specific speed and torque requirements. By collaborating with customers, manufacturers can gather detailed information about the application’s operational parameters, load profiles, and performance expectations. This collaborative approach ensures that the variator gearbox is customized to precisely match the speed and torque ranges needed for the application.

Through variable pulley design, component selection, torque-sensing and control systems, parallel or series configurations, CAD and simulation tools, and collaboration with customers, variator gearboxes can be customized to deliver specific speed and torque ranges. This customization capability allows variator gearboxes to be tailored to a wide range of industrial applications, ensuring optimal performance and efficiency.

Are there specific designs of variator gearboxes for different load conditions?

Yes, variator gearboxes can have specific designs tailored for different load conditions. The design considerations for variator gearboxes take into account the torque requirements, load conditions, and mechanical constraints of the specific application. Here are some common design variations based on load conditions:

- High Torque Applications: Some variator gearboxes are specifically designed to handle high torque applications. These gearboxes are built with robust components and materials capable of transmitting and withstanding substantial torque loads. They may incorporate features such as reinforced gears, larger bearings, and enhanced lubrication systems to ensure reliable torque transmission and durability under heavy loads. Examples of high torque variator gearboxes can be found in heavy machinery, construction equipment, and marine propulsion systems.

- Variable Load Conditions: Variator gearboxes designed for variable load conditions often incorporate adaptive control mechanisms. These gearboxes can adjust their operating parameters, such as gear ratio or hydraulic pressure, in response to changes in the load. By continuously monitoring the load conditions, they optimize the speed and torque output to match the requirements of the varying load, improving efficiency and performance. Variable load variator gearboxes are commonly used in applications where the load conditions can change dynamically, such as in industrial machinery, material handling systems, and automotive transmissions.

- Precision and Low Torque Applications: For applications that require precise speed control and low torque transmission, variator gearboxes with high accuracy and fine adjustment capabilities are employed. These gearboxes are designed to provide smooth and precise speed variations with minimal backlash or hysteresis. They may incorporate features like high-resolution position sensors, fine-tuned control algorithms, and high-precision mechanical components to achieve the desired level of accuracy. Precision variator gearboxes find applications in fields such as scientific instruments, laboratory equipment, and precision manufacturing processes.

- High-Speed Applications: Variator gearboxes designed for high-speed applications focus on minimizing rotational inertia and reducing internal friction. They are engineered to handle the challenges associated with high rotational speeds, such as centrifugal forces, heat generation, and vibration. These gearboxes often employ lightweight materials, aerodynamic designs, and advanced bearing systems to ensure smooth operation and minimize energy losses. High-speed variator gearboxes can be found in applications such as turbine generators, centrifugal compressors, and high-speed machining equipment.

- Specialized Load Conditions: In certain industries or specific applications, variator gearboxes are designed to handle specialized load conditions. These gearboxes may incorporate unique features or mechanisms tailored to the specific requirements of the application. For example, in off-road vehicles, variator gearboxes designed for rough terrains and heavy-duty applications may have reinforced casings, sealed components, and enhanced protection against dust, water, and impact. Similarly, in extreme temperature environments, variator gearboxes may be designed with specialized materials and cooling systems to ensure reliable operation under extreme heat or cold conditions.

These are just a few examples of the specific designs of variator gearboxes for different load conditions. The design of a variator gearbox is influenced by the load characteristics, performance requirements, and environmental factors of the intended application. By tailoring the design to the specific load conditions, variator gearboxes can optimize their performance, efficiency, and durability in various industrial and mechanical systems.

editor by CX 2024-04-22