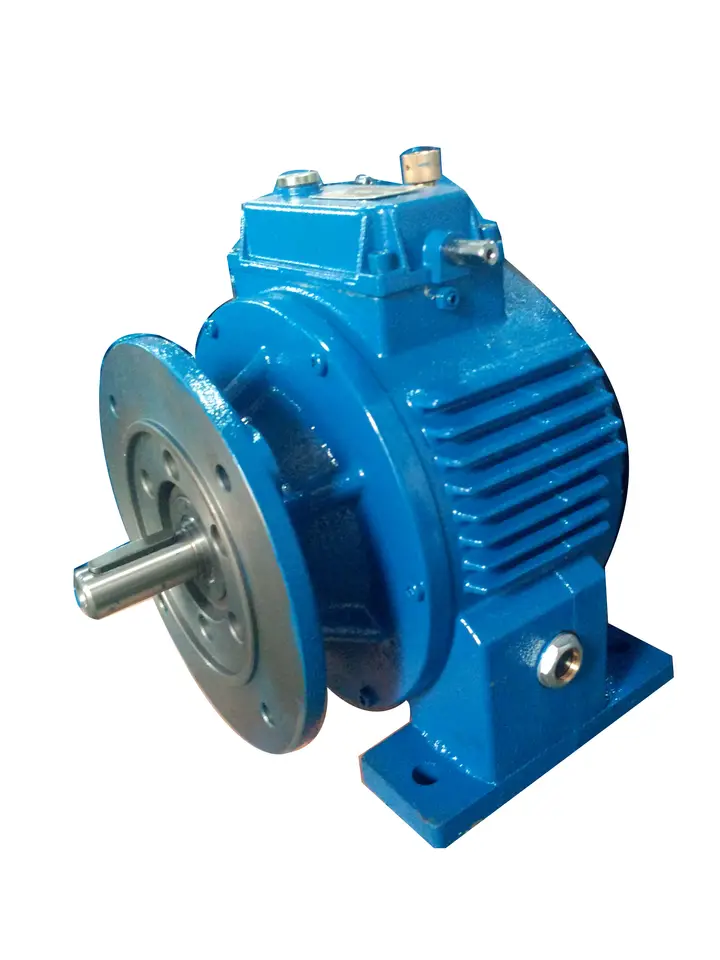

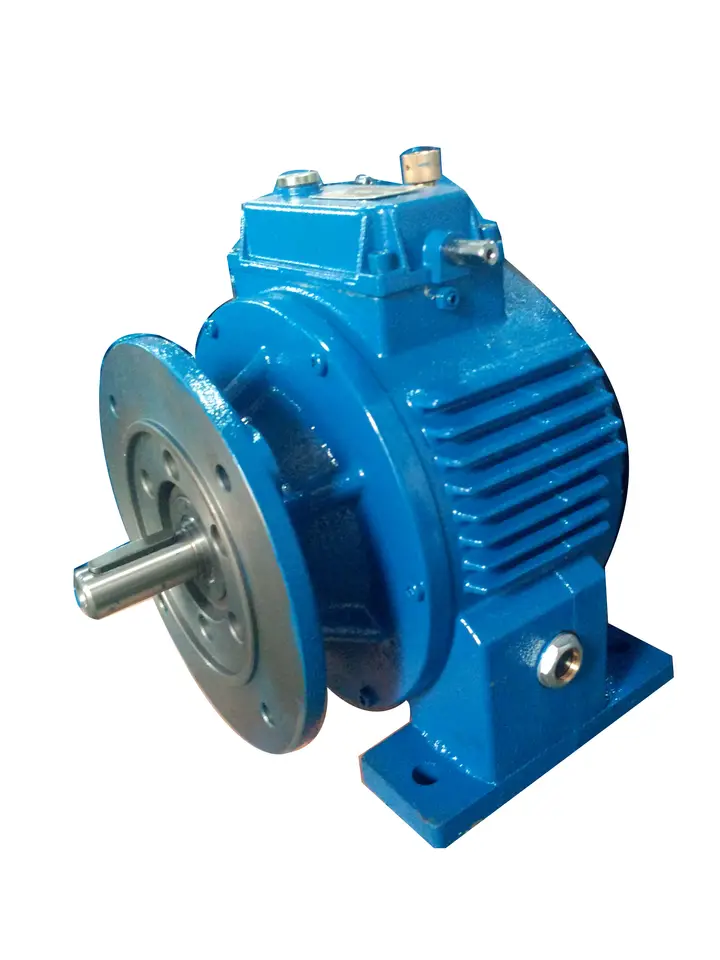

Product Description

1) High precision of speed regulating for speed variator,UD gear box: up to 0.5-1 round

2) Large speed-changing range: the speed ratio ranges from 1:1.4 to 1:7 freely

3) High intensity and long serving time

4) Convenient to regulate speed

5) Continuously workable, bidirectional working direction,smooth running,

stable, and quiet

6) Fully sealed and suitable to any environment

7) Compact structure, small size

8) High quality aluminum alloy die-cast, elegant shape, light weight and non-rusting

9) Good adaptability: can be combined with all kinds of reducers to achieve low

stepless speed changing

10) Input power: 0.18-7.5kW

| Power | Model | I | n2(r/min) | M2(NM) |

| 0.18kw | UDL0.18 | 1.6-8.2 | 880-170 | 1.5~3 |

| 0.37kw | UDL0.37 | 1.4-7 | 1000-200 | 3~6 |

| 0.55kw | UDL0.55 | 1.4-7 | 1000-200 | 4~8 |

| 0.75kw | UDL0.75 | 1.4-7 | 1000-200 | 6~12 |

| 1.1kw | UD1.1 | 1.4-7 | 1000-200 | 9~18 |

| 1.5kw | UD1.5 | 1.4-7 | 1000-200 | 12~24 |

| 2.2kw | UD2.2 | 1.4-7 | 1000-200 | 18~36 |

| 3kw | UD3 | 1.4-7 | 1000-200 | 24~48 |

| 4kw | UD4 | 1.4-7 | 1000-200 | 32-64 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery |

|---|---|

| Output Speed: | 1000-200r/M |

| Input Speed: | 1400rpm |

| Power: | 1.1kw-7.5kw |

| Color: | Blue/Silver White |

| Mounting: | Foot Mounting/Flange Mounting |

| Customization: |

Available

| Customized Request |

|---|

How do variator gearboxes handle changes in speed while maintaining efficiency?

Variator gearboxes are designed to handle changes in speed while maintaining efficiency through their unique construction and control mechanisms. Here’s how variator gearboxes achieve efficient speed handling:

Continuous Adjustment:

Variator gearboxes offer continuous and stepless adjustment of the gear ratio or speed control mechanism. This feature allows for precise control of the output speed, enabling efficient handling of speed changes. By continuously adjusting the gear ratio, variator gearboxes can match the desired output speed while minimizing energy losses and maintaining overall efficiency.

Responsive Control Mechanisms:

Variator gearboxes incorporate control mechanisms that respond quickly to speed adjustment inputs. These control mechanisms can be mechanical, hydraulic, electronic, or a combination of these. When a change in speed is required, the control system activates and adjusts the variator mechanism to modify the gear ratio accordingly. The responsiveness of these control mechanisms ensures that speed changes can be executed promptly and efficiently.

Optimized Gear Design:

Variator gearboxes are engineered with optimized gear designs that minimize energy losses during speed changes. The gear profiles, tooth shapes, and gear ratios are carefully designed to reduce friction and improve the meshing efficiency between the gears. This optimization helps to maintain high power transmission efficiency even during speed adjustments, allowing the gearbox to handle changes in speed efficiently.

Stable Speed Maintenance:

Variator gearboxes are designed to maintain the selected speed setting with high stability. Once the desired speed is achieved, the gearbox is engineered to minimize speed variations due to external load changes or disturbances. This stability ensures that the output speed remains consistent, contributing to efficient speed handling. By minimizing speed fluctuations, variator gearboxes can prevent unnecessary energy losses and maintain overall efficiency.

Feedback and Control Systems:

Some variator gearboxes incorporate feedback and control systems that monitor the output speed and adjust the gear ratio or control parameters accordingly. These systems provide closed-loop control, constantly comparing the actual speed with the desired speed and making adjustments to maintain efficient speed handling. By continuously monitoring and fine-tuning the gear ratio, the gearbox can adapt to changing speed requirements while optimizing efficiency.

Wide Speed Range:

Variator gearboxes offer a wide range of achievable speeds, allowing for flexibility in speed handling. They can cover a broad spectrum of speed requirements by adjusting the gear ratio or other speed control mechanisms. This wide speed range enables efficient speed handling across different operating conditions and applications, ensuring that the gearbox can operate at its optimal efficiency throughout the speed range.

By incorporating continuous adjustment, responsive control mechanisms, optimized gear design, stable speed maintenance, feedback and control systems, and a wide speed range, variator gearboxes can handle changes in speed efficiently while maintaining high power transmission efficiency. These features make them well-suited for applications that require precise and efficient speed handling.

Can variator gearboxes be customized for specific speed and torque ranges?

Yes, variator gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer the flexibility to design and configure variator gearboxes according to the specific needs of customers. Here’s how variator gearboxes can be customized for specific speed and torque ranges:

Variable Pulley Design:

The design of the variable pulley system in a variator gearbox can be customized to achieve desired speed and torque ranges. The shape, size, and configuration of the pulleys can be adjusted to provide different gear ratios and accommodate specific application requirements. By modifying the pulley’s dimensions and angles, variator gearboxes can achieve a wide range of speed ratios and corresponding torque outputs, allowing customization for specific speed and torque ranges.

Selection of Components:

Manufacturers can select and optimize various components within the variator gearbox to match specific speed and torque ranges. This includes the choice of materials for gears, bearings, and other critical components. By selecting appropriate materials, manufacturers can ensure that the variator gearbox can handle the required torque levels without compromising its durability and performance.

Torque-Sensing and Control Systems:

The torque-sensing and control systems within variator gearboxes can be customized to provide precise control over speed and torque. Manufacturers can incorporate sensors and control algorithms that are tailored to the specific speed and torque requirements of an application. These systems monitor the torque load and adjust the gear ratio accordingly to maintain the desired speed and torque output, allowing for customization within specific ranges.

Applications in Parallel or Series:

In some cases, multiple variator gearboxes can be configured in parallel or series to achieve the desired speed and torque ranges. By combining the outputs of multiple variator gearboxes, either in parallel or series arrangement, the overall speed and torque capabilities can be customized to meet specific application requirements. This configuration allows for scalability and adaptability to different speed and torque demands.

Computer-Aided Design (CAD) and Simulation:

Manufacturers utilize computer-aided design (CAD) software and simulations to customize variator gearboxes for specific speed and torque ranges. CAD tools enable the design and optimization of components, ensuring they can withstand the required torque levels and operate within the desired speed ranges. Simulations help manufacturers evaluate the performance of the customized variator gearbox under different operating conditions, allowing for fine-tuning and optimization.

Collaboration with Customers:

Manufacturers work closely with customers to understand their specific speed and torque requirements. By collaborating with customers, manufacturers can gather detailed information about the application’s operational parameters, load profiles, and performance expectations. This collaborative approach ensures that the variator gearbox is customized to precisely match the speed and torque ranges needed for the application.

Through variable pulley design, component selection, torque-sensing and control systems, parallel or series configurations, CAD and simulation tools, and collaboration with customers, variator gearboxes can be customized to deliver specific speed and torque ranges. This customization capability allows variator gearboxes to be tailored to a wide range of industrial applications, ensuring optimal performance and efficiency.

Can you explain the different types of variator gearboxes and their functions?

There are several different types of variator gearboxes, each with its own design and function. Here are some of the common types:

- Belt-and-Pulley Variators: Belt-and-pulley variators, also known as variable speed drives or variable speed transmissions (VSTs), use a belt and a set of variable diameter pulleys to achieve speed variation. The pulleys can change their effective diameter by adjusting their position, allowing for continuous adjustment of the output speed. Belt-and-pulley variators are commonly used in applications such as vehicles, industrial machinery, and power transmission systems.

- Cone Variators: Cone variators, also called toroidal or traction drive variators, use a pair of conical disks or rollers to achieve speed variation. The conical elements have varying radii, and their contact point determines the output speed. As the cones move closer or farther apart, the effective radius changes, resulting in speed adjustment. Cone variators are often employed in applications where compact size, high torque capacity, and high efficiency are desired, such as in automotive transmissions and industrial power transmission systems.

- Disc Variators: Disc variators, also known as disc drives or disk-and-roll variators, use a set of interlocking discs and rollers to achieve speed variation. The discs have spiral grooves that guide the movement of the rollers. By adjusting the axial position of the rollers, the effective diameter of the variator changes, leading to speed control. Disc variators are commonly used in applications where high torque capacity and precise speed control are required, such as in heavy machinery, construction equipment, and marine propulsion systems.

- Hydrostatic Variators: Hydrostatic variators use hydraulic systems to achieve speed variation. They typically consist of a pump, a motor, and a control valve. The pump supplies hydraulic fluid under pressure, which drives the motor to generate rotational motion. By controlling the flow rate and pressure of the hydraulic fluid, the output speed can be adjusted. Hydrostatic variators are commonly used in applications that require high torque, precise control, and the ability to handle heavy loads, such as in construction machinery, agricultural equipment, and machine tools.

- Torque Converter Variators: Torque converter variators, also known as fluid couplings, use a fluid-filled chamber to transmit torque and achieve speed variation. They consist of an impeller, a turbine, and a stator. The impeller and turbine are connected to the input and output shafts, respectively, and the stator redirects the fluid flow. By altering the fluid flow characteristics, torque converter variators allow for speed control. They are commonly used in automotive automatic transmissions and heavy-duty industrial applications.

Each type of variator gearbox offers specific advantages and is suitable for different applications based on factors such as torque requirements, speed range, efficiency, compactness, and control options. The selection of the appropriate variator gearbox depends on the specific needs and constraints of the application at hand.

In summary, the different types of variator gearboxes include belt-and-pulley variators, cone variators, disc variators, hydrostatic variators, and torque converter variators. Each type has its own design and function, providing a range of options for achieving continuous and stepless speed variation in various mechanical systems.

editor by CX 2024-04-08