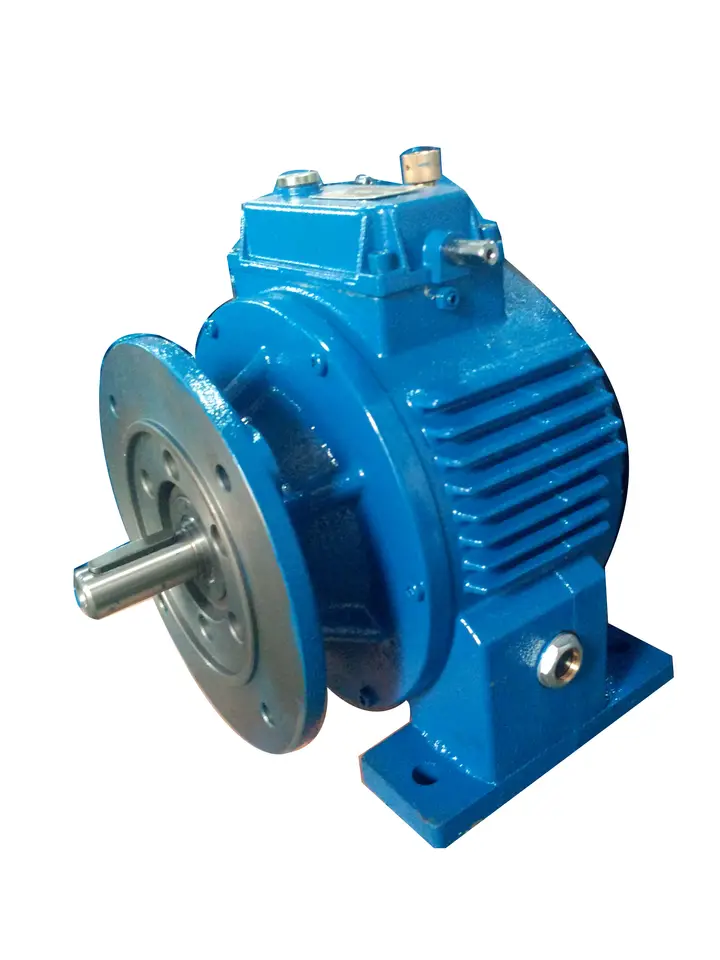

Product Description

Product Description

Components:

1. Housing: Aluminium alloy(udl series) cast iron(ud series)

2. Input configurations:

Equipped with electric motors

IEC-normalized motor flange

3. Output configurations:

CHINAMFG shaft output

CHINAMFG shaft output with output flange

Models:

Foot mounted – udl002b3~ud050b3

Flange mounted – udl002b5~ud050b5

Features:

1. Adjustable speed span can be accurate to 0.5~1 r/min

2. Can be combined with other types of gearboxes (such as r series, k series, f series, s series, RV series, wb series cycloid reducers)

3. Compact structure

4. Clockwise and counterclockwise rotation

Detailed Photos

Installation:

B3 Foot-mounted

B5 Flange-mounted

Material:

Housing: Aluminium or ht250 cast iron.

Gear: 20crmnti h, high grade allo with carburization, surface hardness: 58-62HRC, center hardness: 33-48HRC

Grinding precision grade: ISO1328-1: 1995 class 5-6, surfaceness: 0.8, carburization depth: 0.6-1.5mm

Bearing: 42CrMo

Product Parameters

Parameters:

| Models | Power | Ratio | Output speed(n2)* | Output torque | Output shaft dia. | Output flange dia. |

| Udl002 | 0.18kw | 1.6~8.2 | 800~170r/min | 1.5~3n. M | Φ11 | Φ140 |

| Udl005 | 0.25kw | 1.4~7 | 1000~200r/min | 2.2~6n. M | Φ14 | Φ160 |

| Udl005 | 0.37kw | 1.4~7 | 1000~200r/min | 3~6n. M | Φ14 | Φ160 |

| Udl571 | 0.55kw | 1.4~7 | 1000~200r/min | 4~8n. M | Φ19 | Φ200 |

| Udl571 | 0.75kw | 1.4~7 | 1000~200r/min | 6~12n. M | Φ19 | Φ200 |

* input speed n1=1400r/min

Commercial information:

| MOQ | 1 piece |

| Package | Plywood case/wooden case |

| Delivery | 20-25 days |

| Payment terms | Fob, CIF, CFR |

| Payment methods | T/T, 30% in advance, 70% before delivery |

| Shipping port | ZheJiang |

Packaging & Shipping

Company Profile

Our Advantages

Our superiority:

1. Delivery on time.

2. Professional service: Customized is our advantage.

3. Good quality.

4. Fast and low cost deliver: Long-term cooperated shipping forwarders.

Our services:

| Pre-sale services | 1. Select equipment model. |

| 2. Design and manufacture products according to clients’ special requirement. | |

| 3. Train technical personal for clients | |

| Services during selling | 1. Pre-check and accept products ahead of delivery. |

| 2. Help clients to draft solving plans | |

| After-sale services | 1. Assist clients to prepare for the first construction scheme. |

| 2. Train the first-line operators. | |

| 3. Take initiative to eliminate the trouble rapidly. | |

| 4. Provide technical exchanging. |

FAQ

1.Q:What kinds of gearbox can you produce for us?

A:Main products of our company: UDL series speed variator,RV series worm gear reducer, ATA series shaft mounted gearbox, X,B series gear reducer,P series planetary gearbox and R, S, K, and F series helical-tooth reducer, more than 1 hundred models and thousands of specifications

2.Q:Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

3.Q:What is your terms of payment ?

A: 30% Advance payment by T/T after signing the contract.70% before delivery

4.Q:What is your MOQ?

A: 1 Set

If you have any demand for our products please feel free to contact me /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Helical Gear |

| Step: | Stepless |

| Customization: |

Available

| Customized Request |

|---|

How do variator gearboxes handle changes in speed while maintaining efficiency?

Variator gearboxes are designed to handle changes in speed while maintaining efficiency through their unique construction and control mechanisms. Here’s how variator gearboxes achieve efficient speed handling:

Continuous Adjustment:

Variator gearboxes offer continuous and stepless adjustment of the gear ratio or speed control mechanism. This feature allows for precise control of the output speed, enabling efficient handling of speed changes. By continuously adjusting the gear ratio, variator gearboxes can match the desired output speed while minimizing energy losses and maintaining overall efficiency.

Responsive Control Mechanisms:

Variator gearboxes incorporate control mechanisms that respond quickly to speed adjustment inputs. These control mechanisms can be mechanical, hydraulic, electronic, or a combination of these. When a change in speed is required, the control system activates and adjusts the variator mechanism to modify the gear ratio accordingly. The responsiveness of these control mechanisms ensures that speed changes can be executed promptly and efficiently.

Optimized Gear Design:

Variator gearboxes are engineered with optimized gear designs that minimize energy losses during speed changes. The gear profiles, tooth shapes, and gear ratios are carefully designed to reduce friction and improve the meshing efficiency between the gears. This optimization helps to maintain high power transmission efficiency even during speed adjustments, allowing the gearbox to handle changes in speed efficiently.

Stable Speed Maintenance:

Variator gearboxes are designed to maintain the selected speed setting with high stability. Once the desired speed is achieved, the gearbox is engineered to minimize speed variations due to external load changes or disturbances. This stability ensures that the output speed remains consistent, contributing to efficient speed handling. By minimizing speed fluctuations, variator gearboxes can prevent unnecessary energy losses and maintain overall efficiency.

Feedback and Control Systems:

Some variator gearboxes incorporate feedback and control systems that monitor the output speed and adjust the gear ratio or control parameters accordingly. These systems provide closed-loop control, constantly comparing the actual speed with the desired speed and making adjustments to maintain efficient speed handling. By continuously monitoring and fine-tuning the gear ratio, the gearbox can adapt to changing speed requirements while optimizing efficiency.

Wide Speed Range:

Variator gearboxes offer a wide range of achievable speeds, allowing for flexibility in speed handling. They can cover a broad spectrum of speed requirements by adjusting the gear ratio or other speed control mechanisms. This wide speed range enables efficient speed handling across different operating conditions and applications, ensuring that the gearbox can operate at its optimal efficiency throughout the speed range.

By incorporating continuous adjustment, responsive control mechanisms, optimized gear design, stable speed maintenance, feedback and control systems, and a wide speed range, variator gearboxes can handle changes in speed efficiently while maintaining high power transmission efficiency. These features make them well-suited for applications that require precise and efficient speed handling.

Can variator gearboxes be customized for specific speed and torque ranges?

Yes, variator gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer the flexibility to design and configure variator gearboxes according to the specific needs of customers. Here’s how variator gearboxes can be customized for specific speed and torque ranges:

Variable Pulley Design:

The design of the variable pulley system in a variator gearbox can be customized to achieve desired speed and torque ranges. The shape, size, and configuration of the pulleys can be adjusted to provide different gear ratios and accommodate specific application requirements. By modifying the pulley’s dimensions and angles, variator gearboxes can achieve a wide range of speed ratios and corresponding torque outputs, allowing customization for specific speed and torque ranges.

Selection of Components:

Manufacturers can select and optimize various components within the variator gearbox to match specific speed and torque ranges. This includes the choice of materials for gears, bearings, and other critical components. By selecting appropriate materials, manufacturers can ensure that the variator gearbox can handle the required torque levels without compromising its durability and performance.

Torque-Sensing and Control Systems:

The torque-sensing and control systems within variator gearboxes can be customized to provide precise control over speed and torque. Manufacturers can incorporate sensors and control algorithms that are tailored to the specific speed and torque requirements of an application. These systems monitor the torque load and adjust the gear ratio accordingly to maintain the desired speed and torque output, allowing for customization within specific ranges.

Applications in Parallel or Series:

In some cases, multiple variator gearboxes can be configured in parallel or series to achieve the desired speed and torque ranges. By combining the outputs of multiple variator gearboxes, either in parallel or series arrangement, the overall speed and torque capabilities can be customized to meet specific application requirements. This configuration allows for scalability and adaptability to different speed and torque demands.

Computer-Aided Design (CAD) and Simulation:

Manufacturers utilize computer-aided design (CAD) software and simulations to customize variator gearboxes for specific speed and torque ranges. CAD tools enable the design and optimization of components, ensuring they can withstand the required torque levels and operate within the desired speed ranges. Simulations help manufacturers evaluate the performance of the customized variator gearbox under different operating conditions, allowing for fine-tuning and optimization.

Collaboration with Customers:

Manufacturers work closely with customers to understand their specific speed and torque requirements. By collaborating with customers, manufacturers can gather detailed information about the application’s operational parameters, load profiles, and performance expectations. This collaborative approach ensures that the variator gearbox is customized to precisely match the speed and torque ranges needed for the application.

Through variable pulley design, component selection, torque-sensing and control systems, parallel or series configurations, CAD and simulation tools, and collaboration with customers, variator gearboxes can be customized to deliver specific speed and torque ranges. This customization capability allows variator gearboxes to be tailored to a wide range of industrial applications, ensuring optimal performance and efficiency.

How do variator gearboxes contribute to continuously adjustable speed control?

Variator gearboxes play a significant role in providing continuously adjustable speed control in mechanical systems. They offer several key features and mechanisms that enable this capability:

- Stepless Speed Variation: Variator gearboxes allow for stepless and continuous adjustment of the output speed within a certain range. Unlike traditional gearboxes with fixed gear ratios, variators provide infinite possibilities for speed control. This feature enables precise and fine-tuned speed adjustments, allowing for optimal performance in various applications.

- Variable Diameter Pulleys: One common mechanism used in variator gearboxes is the variable diameter pulley system. This system consists of two pulleys connected by a belt. By adjusting the position of the pulleys, the effective diameter of the pulleys changes, altering the speed ratio between the input and output. This variable diameter pulley mechanism enables continuous adjustment of the output speed, providing the basis for continuously adjustable speed control.

- Smooth and Continuous Transitions: Variator gearboxes offer smooth and seamless transitions between different output speeds. As the pulley diameters are adjusted, the belt smoothly moves along the pulleys without sudden jumps or changes. This allows for precise and gradual speed control, ensuring smooth operation and minimizing any potential disruptions or vibrations in the mechanical system.

- Manual or Automatic Control: Variator gearboxes can be controlled manually or automatically, depending on the specific application. In manual systems, operators can adjust the pulley positions using mechanical or hydraulic mechanisms. Automatic systems, on the other hand, employ computer control or electronic control units (ECUs) to dynamically adjust the pulley positions based on various parameters such as speed, load, or user inputs. This flexibility in control options allows for efficient and convenient speed adjustments in different operating conditions.

- Wide Speed Range: Variator gearboxes typically offer a wide range of speed adjustment. The specific speed range depends on the design and capabilities of the gearbox. Some variators can achieve significant speed reductions or increases, allowing for versatile speed control in applications where a wide range of speeds is required.

The continuously adjustable speed control provided by variator gearboxes is beneficial in numerous applications. For example, in vehicles, variators are used in continuously variable transmissions (CVTs) to optimize engine performance and fuel efficiency. In industrial machinery, variators allow for precise control of rotational speeds in processes such as machining, material handling, and conveyor systems. Additionally, variators find applications in power transmission systems, where they enable efficient and flexible speed adjustments in generators, pumps, and other equipment.

In summary, variator gearboxes contribute to continuously adjustable speed control through their stepless speed variation, variable diameter pulley mechanisms, smooth transitions, manual or automatic control options, and wide speed range. These features make variator gearboxes valuable components in achieving precise and efficient speed control in various mechanical systems.

editor by CX 2024-04-11