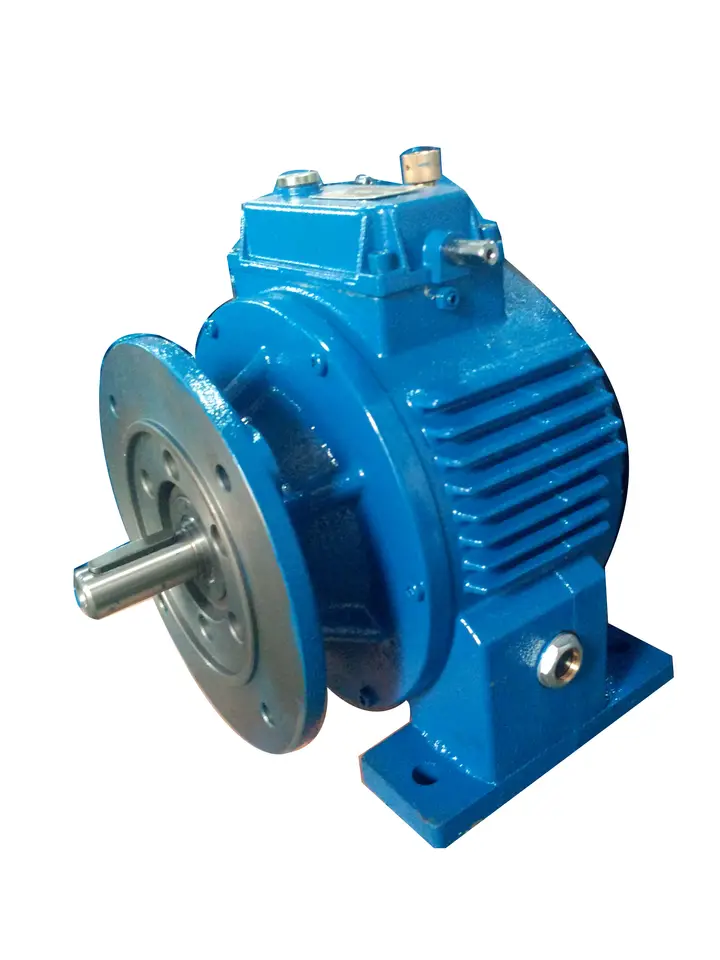

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do variator gearboxes contribute to optimizing the efficiency of conveyor systems?

Variator gearboxes play a crucial role in optimizing the efficiency of conveyor systems. They offer several advantages that contribute to improved performance, energy efficiency, and overall productivity. Here’s how variator gearboxes help optimize the efficiency of conveyor systems:

- Variable Speed Control: Variator gearboxes enable precise and continuous adjustment of the conveyor’s speed. This variable speed control allows operators to match the conveyor’s speed to the specific requirements of the material being transported or the production process. By running the conveyor at the optimal speed, energy wastage is minimized, and the system operates more efficiently.

- Load Adaptability: Conveyor systems often handle varying loads or different types of materials. Variator gearboxes offer load adaptability, allowing the conveyor to adjust its speed and torque output based on the applied load. This adaptability ensures that the conveyor operates at the appropriate power level, minimizing energy waste during periods of low load or when handling lighter materials.

- Smooth Starting and Stopping: Variator gearboxes provide smooth acceleration and deceleration capabilities, allowing the conveyor to start and stop gradually. This feature reduces stress on the conveyor components, minimizes jerky movements, and prevents material spillage. Smooth starting and stopping also contribute to energy efficiency by reducing power surges and mechanical stress on the system.

- Optimized Power Transmission: Variator gearboxes are designed to optimize power transmission efficiency. They utilize efficient power transfer mechanisms, such as belts or chains, along with well-engineered pulley systems. These systems minimize power losses due to friction and slippage, ensuring that a greater percentage of input power is effectively delivered to the conveyor belt, reducing power consumption.

- Customizable Gear Ratios: Variator gearboxes offer a wide range of gear ratios that can be adjusted based on the specific conveyor requirements. By selecting the optimal gear ratio, the variator gearbox ensures efficient power transfer and reduced power losses. The customizable gear ratios allow the conveyor to operate at the most favorable speed and torque combination, maximizing energy efficiency.

- Integrated Control Systems: Variator gearboxes can be integrated with advanced control systems and automation technologies. These systems enable precise control over the conveyor’s speed, acceleration, and deceleration profiles. By implementing intelligent control algorithms, variator gearboxes can optimize the conveyor’s operation based on real-time production demands, minimizing power consumption and maximizing productivity.

- Maintenance and Serviceability: Variator gearboxes often offer ease of maintenance and serviceability features. They may incorporate features like quick belt tension adjustment mechanisms, easy access to components for inspection and maintenance, and built-in condition monitoring systems. These features simplify maintenance tasks, reduce downtime, and ensure that the gearbox operates at its peak efficiency.

By leveraging the variable speed control, load adaptability, smooth starting and stopping, optimized power transmission, customizable gear ratios, integrated control systems, and maintenance features, variator gearboxes contribute to the overall optimization of conveyor system efficiency. They enable energy-efficient operation, reduce power consumption, enhance material handling capabilities, and improve the productivity and reliability of conveyor systems in various industries.

How do manufacturers ensure the durability of variator gearboxes in industrial environments?

Manufacturers employ various strategies and techniques to ensure the durability of variator gearboxes in industrial environments. These measures are implemented during the design, construction, and testing stages to enhance the gearbox’s ability to withstand the harsh conditions and rigorous demands of industrial applications. Here’s how manufacturers ensure the durability of variator gearboxes:

Rugged Construction:

Manufacturers use robust and durable materials for constructing variator gearboxes. High-quality metals, such as steel or cast iron, are commonly used for gearbox housings and essential components. These materials possess excellent strength, wear resistance, and thermal stability, enabling the gearbox to withstand heavy loads, vibrations, and temperature variations typically encountered in industrial environments.

Enhanced Gear Design:

The gear design of variator gearboxes is optimized for durability. Manufacturers carefully select gear materials, tooth profiles, and surface treatments to minimize wear, improve load distribution, and enhance the gearbox’s ability to handle torque and shock loads. Advanced manufacturing techniques, such as precision machining and heat treatment processes, are employed to ensure the gears have the required hardness, toughness, and dimensional accuracy for long-lasting performance.

Sealing and Protection:

Variator gearboxes are equipped with effective sealing systems to prevent the ingress of contaminants, such as dust, dirt, and moisture, into the gearbox. Seals, gaskets, and O-rings are used to create a barrier that protects internal components from environmental elements. Additionally, manufacturers often incorporate protective measures, such as breather vents or pressure relief valves, to maintain an appropriate internal pressure and prevent the buildup of excessive heat or pressure that could compromise the gearbox’s durability.

Effective Lubrication:

Proper lubrication is critical for the durability of variator gearboxes. Manufacturers ensure that the gearbox is designed with efficient lubrication systems that provide adequate lubricant flow to all critical components. This lubrication helps reduce friction, dissipate heat, and prevent excessive wear and corrosion. Manufacturers may also specify the use of specific lubricants that are suitable for the operating conditions and requirements of the variator gearbox, further enhancing its durability.

Thorough Testing and Quality Control:

Manufacturers subject variator gearboxes to rigorous testing procedures to validate their durability in industrial environments. These tests may include load testing, endurance testing, temperature cycling, and performance verification. Through comprehensive testing, manufacturers can identify potential weaknesses or design flaws and make necessary improvements to ensure the gearbox’s durability. Additionally, stringent quality control measures are implemented throughout the manufacturing process to maintain consistency and reliability in the production of variator gearboxes.

Compliance with Standards and Regulations:

Manufacturers adhere to industry standards and regulations to ensure the durability and safety of variator gearboxes. Compliance with standards, such as ISO (International Organization for Standardization) and specific industry guidelines, helps manufacturers design and manufacture gearboxes that meet or exceed the required performance and durability criteria. This ensures that the variator gearboxes are suitable for use in industrial environments and can withstand the demanding operating conditions they may encounter.

By employing rugged construction, enhanced gear design, sealing and protection measures, effective lubrication systems, thorough testing and quality control, and compliance with standards and regulations, manufacturers ensure the durability of variator gearboxes in industrial environments. These measures contribute to the reliability, longevity, and performance of variator gearboxes, making them well-suited for demanding industrial applications.

What is a variator gearbox and how does it work in mechanical systems?

A variator gearbox, also known as a variable speed transmission, is a type of gearbox that allows for continuous and stepless variation of the output speed within a certain range. It is commonly used in mechanical systems where the output speed needs to be adjusted dynamically without fixed gear ratios. The variator gearbox achieves this by employing specific mechanisms such as belts, chains, or cones.

One common type of variator gearbox is the belt-and-pulley system. It consists of two variable-diameter pulleys connected by a belt. These pulleys can change their effective diameter by adjusting their position. The input pulley is connected to the power source, such as an engine or motor, while the output pulley is connected to the load. By varying the diameters of the pulleys, the speed ratio between the input and output can be continuously adjusted, allowing for a wide range of output speeds.

The variator gearbox works based on the principle of changing the effective radius of the pulleys. When the input pulley diameter increases or the output pulley diameter decreases, the belt is forced to ride higher on the pulley, resulting in a larger effective radius. This causes the output speed to decrease relative to the input speed. Conversely, when the input pulley diameter decreases or the output pulley diameter increases, the belt rides lower on the pulley, leading to a smaller effective radius and an increase in the output speed.

The variator gearbox can be controlled manually or automatically, depending on the application. In manual systems, the adjustment of the pulley diameters is done by the operator using mechanical or hydraulic mechanisms. In automatic systems, the adjustment is typically controlled by a computer or an electronic control unit (ECU) based on various parameters such as speed, load, or user inputs.

One of the key advantages of variator gearboxes is the ability to achieve smooth and stepless speed variation. Unlike traditional gearboxes with fixed gear ratios, variator gearboxes offer infinite possibilities for adjusting the output speed. This flexibility is particularly beneficial in applications where precise control of speed is required, such as in vehicles, industrial machinery, and power transmission systems.

However, it’s important to note that variator gearboxes may have limitations in terms of torque capacity and efficiency compared to traditional fixed-ratio gearboxes. The power transmission efficiency of variator gearboxes can vary depending on the specific design and operating conditions.

In summary, a variator gearbox is a type of gearbox that allows for continuous and stepless variation of the output speed. It uses mechanisms such as belts, chains, or cones to adjust the effective diameter of the pulleys, enabling dynamic speed control in mechanical systems.

editor by CX 2024-05-07