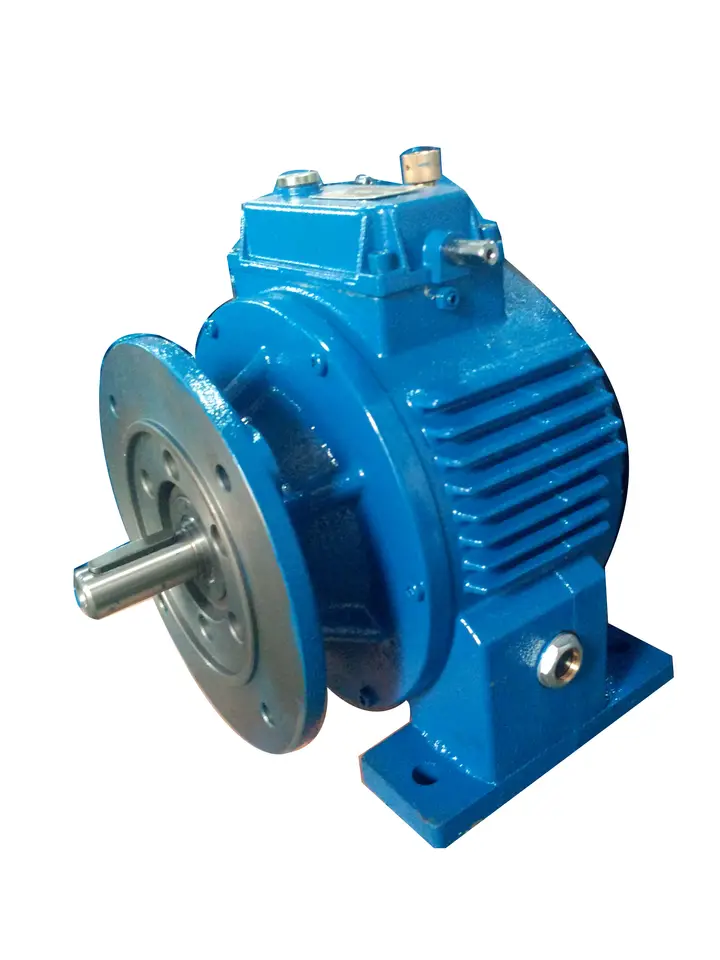

Product Description

Features

1.Wide transmission rate, strong output torque

2.Compact mechanical structure, light weight, small volume&Good heat-dissipating

3.Smooth operation with lower noise or vibration

4.Easy mounting, free linking, high efficiency

5. PERFECT SUBSTITUDE FOR MOTOVARIO AND CHINAMFG PRODUCTS

Applications

Wide range of application,including light industry of food &beverage, Cement,

package,construction material,chemicals and etc.

Technical data:

| Model | RV 130 150 |

| Single unit versions | NMRV – fitted for motor flanged coupling, NRV – with input shaft, NMRV-E motor flanged coupling with worm extension shaft, NRV-E with double extension worm shaft, |

| Power | 0.06—-15KW |

| Single unit reduction ratio | 1:5 7.5 80 100 |

| Output torque | 2.6—1195N.M |

| Worm shaft material | 20CrMnTi with carburizing and quenching.The hardness of surface is 56-62HRC with carbonized layer 0.5-0.8mm |

| Worm wheel material | worm mandrel is HT250,and worm ring gear,ZQSn10-1,hardness is 60HRC |

After-sale service:

One year warranty,subject to proper operation and installation;free technical support all the time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor |

|---|---|

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do variator gearboxes handle changes in speed while maintaining efficiency?

Variator gearboxes are designed to handle changes in speed while maintaining efficiency through their unique construction and control mechanisms. Here’s how variator gearboxes achieve efficient speed handling:

Continuous Adjustment:

Variator gearboxes offer continuous and stepless adjustment of the gear ratio or speed control mechanism. This feature allows for precise control of the output speed, enabling efficient handling of speed changes. By continuously adjusting the gear ratio, variator gearboxes can match the desired output speed while minimizing energy losses and maintaining overall efficiency.

Responsive Control Mechanisms:

Variator gearboxes incorporate control mechanisms that respond quickly to speed adjustment inputs. These control mechanisms can be mechanical, hydraulic, electronic, or a combination of these. When a change in speed is required, the control system activates and adjusts the variator mechanism to modify the gear ratio accordingly. The responsiveness of these control mechanisms ensures that speed changes can be executed promptly and efficiently.

Optimized Gear Design:

Variator gearboxes are engineered with optimized gear designs that minimize energy losses during speed changes. The gear profiles, tooth shapes, and gear ratios are carefully designed to reduce friction and improve the meshing efficiency between the gears. This optimization helps to maintain high power transmission efficiency even during speed adjustments, allowing the gearbox to handle changes in speed efficiently.

Stable Speed Maintenance:

Variator gearboxes are designed to maintain the selected speed setting with high stability. Once the desired speed is achieved, the gearbox is engineered to minimize speed variations due to external load changes or disturbances. This stability ensures that the output speed remains consistent, contributing to efficient speed handling. By minimizing speed fluctuations, variator gearboxes can prevent unnecessary energy losses and maintain overall efficiency.

Feedback and Control Systems:

Some variator gearboxes incorporate feedback and control systems that monitor the output speed and adjust the gear ratio or control parameters accordingly. These systems provide closed-loop control, constantly comparing the actual speed with the desired speed and making adjustments to maintain efficient speed handling. By continuously monitoring and fine-tuning the gear ratio, the gearbox can adapt to changing speed requirements while optimizing efficiency.

Wide Speed Range:

Variator gearboxes offer a wide range of achievable speeds, allowing for flexibility in speed handling. They can cover a broad spectrum of speed requirements by adjusting the gear ratio or other speed control mechanisms. This wide speed range enables efficient speed handling across different operating conditions and applications, ensuring that the gearbox can operate at its optimal efficiency throughout the speed range.

By incorporating continuous adjustment, responsive control mechanisms, optimized gear design, stable speed maintenance, feedback and control systems, and a wide speed range, variator gearboxes can handle changes in speed efficiently while maintaining high power transmission efficiency. These features make them well-suited for applications that require precise and efficient speed handling.

Can variator gearboxes be customized for specific speed and torque ranges?

Yes, variator gearboxes can be customized to meet specific speed and torque requirements in various applications. Manufacturers offer the flexibility to design and configure variator gearboxes according to the specific needs of customers. Here’s how variator gearboxes can be customized for specific speed and torque ranges:

Variable Pulley Design:

The design of the variable pulley system in a variator gearbox can be customized to achieve desired speed and torque ranges. The shape, size, and configuration of the pulleys can be adjusted to provide different gear ratios and accommodate specific application requirements. By modifying the pulley’s dimensions and angles, variator gearboxes can achieve a wide range of speed ratios and corresponding torque outputs, allowing customization for specific speed and torque ranges.

Selection of Components:

Manufacturers can select and optimize various components within the variator gearbox to match specific speed and torque ranges. This includes the choice of materials for gears, bearings, and other critical components. By selecting appropriate materials, manufacturers can ensure that the variator gearbox can handle the required torque levels without compromising its durability and performance.

Torque-Sensing and Control Systems:

The torque-sensing and control systems within variator gearboxes can be customized to provide precise control over speed and torque. Manufacturers can incorporate sensors and control algorithms that are tailored to the specific speed and torque requirements of an application. These systems monitor the torque load and adjust the gear ratio accordingly to maintain the desired speed and torque output, allowing for customization within specific ranges.

Applications in Parallel or Series:

In some cases, multiple variator gearboxes can be configured in parallel or series to achieve the desired speed and torque ranges. By combining the outputs of multiple variator gearboxes, either in parallel or series arrangement, the overall speed and torque capabilities can be customized to meet specific application requirements. This configuration allows for scalability and adaptability to different speed and torque demands.

Computer-Aided Design (CAD) and Simulation:

Manufacturers utilize computer-aided design (CAD) software and simulations to customize variator gearboxes for specific speed and torque ranges. CAD tools enable the design and optimization of components, ensuring they can withstand the required torque levels and operate within the desired speed ranges. Simulations help manufacturers evaluate the performance of the customized variator gearbox under different operating conditions, allowing for fine-tuning and optimization.

Collaboration with Customers:

Manufacturers work closely with customers to understand their specific speed and torque requirements. By collaborating with customers, manufacturers can gather detailed information about the application’s operational parameters, load profiles, and performance expectations. This collaborative approach ensures that the variator gearbox is customized to precisely match the speed and torque ranges needed for the application.

Through variable pulley design, component selection, torque-sensing and control systems, parallel or series configurations, CAD and simulation tools, and collaboration with customers, variator gearboxes can be customized to deliver specific speed and torque ranges. This customization capability allows variator gearboxes to be tailored to a wide range of industrial applications, ensuring optimal performance and efficiency.

What benefits do variator gearboxes offer in various industrial applications?

Variator gearboxes offer several benefits in various industrial applications, making them valuable components in numerous systems. Here are some of the key advantages they provide:

- Continuously Adjustable Speed: One of the primary benefits of variator gearboxes is their ability to provide continuously adjustable speed control. Unlike traditional gearboxes with fixed gear ratios, variators offer stepless speed variation within a certain range. This feature allows for precise control of rotational speeds in industrial machinery, optimizing performance and efficiency in different processes.</li

- Optimized Power Efficiency: Variator gearboxes help optimize power efficiency in industrial applications. By allowing for continuous speed adjustment, they enable the machinery to operate at the most efficient speed for a given task. This ensures that the system consumes only the necessary amount of power, minimizing energy waste and reducing operating costs.

- Flexible Torque Transmission: Variator gearboxes can handle a wide range of torque requirements, making them suitable for various industrial applications. They can transmit high torque while maintaining their efficiency, allowing industrial machinery to generate the necessary power for demanding tasks. This flexibility in torque transmission contributes to the versatility and adaptability of variator gearboxes in industrial settings.

- Smooth and Precise Control: Variator gearboxes provide smooth and precise control over rotational speeds. The stepless speed adjustment allows for seamless transitions between different speeds without sudden jumps or changes. This smooth control enhances the precision and accuracy of industrial processes, ensuring consistent performance and high-quality output.

- Improved System Performance: By enabling precise speed control, variator gearboxes enhance the overall performance of industrial systems. They allow machinery to operate at the optimal speed for specific tasks, leading to improved productivity, reduced cycle times, and enhanced product quality. The ability to fine-tune the speed also facilitates better synchronization between different components or processes, further optimizing system performance.

- Reduced Mechanical Stress: Variator gearboxes can help reduce mechanical stress on industrial machinery. By allowing for gradual speed adjustments, they minimize sudden changes in load or torque, which can put excessive stress on components. This reduction in mechanical stress contributes to extended equipment lifespan, reduced maintenance requirements, and improved reliability in industrial applications.

- Adaptability to Changing Conditions: Variator gearboxes offer adaptability to changing operating conditions. They allow for real-time adjustments in speed, which is particularly beneficial in applications where the load or process requirements vary. This adaptability enables industrial machinery to respond quickly to changing demands, ensuring optimal performance and efficiency in dynamic environments.

In summary, variator gearboxes provide benefits such as continuously adjustable speed control, optimized power efficiency, flexible torque transmission, smooth and precise control, improved system performance, reduced mechanical stress, and adaptability to changing conditions. These advantages make variator gearboxes valuable in various industrial applications, including manufacturing, material handling, packaging, robotics, and many others, where precise speed control and efficient power transmission are essential.

editor by CX 2024-04-25