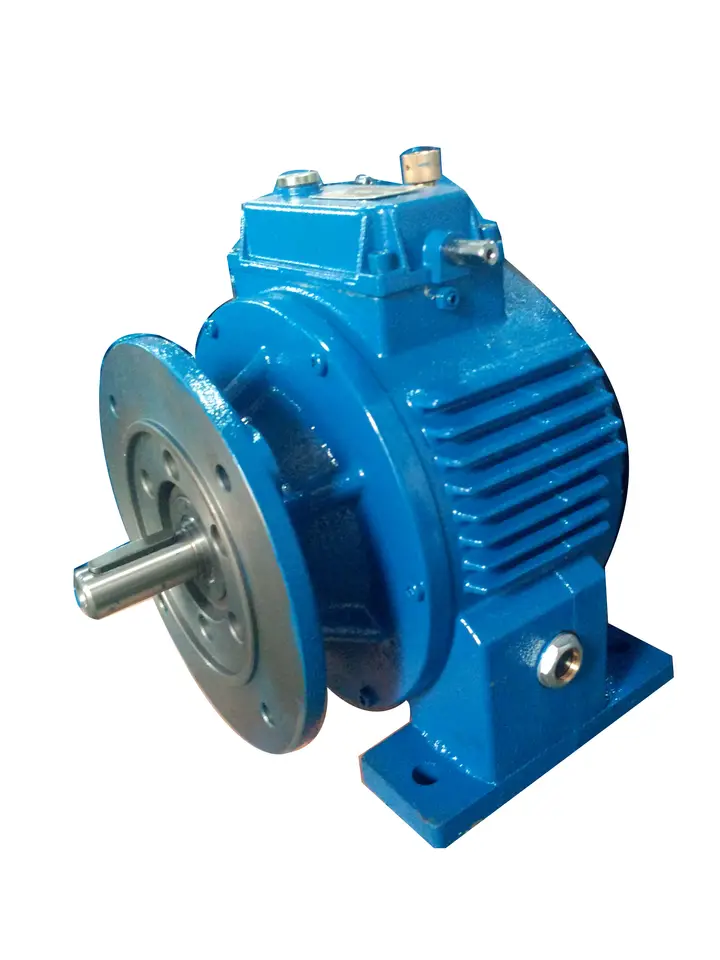

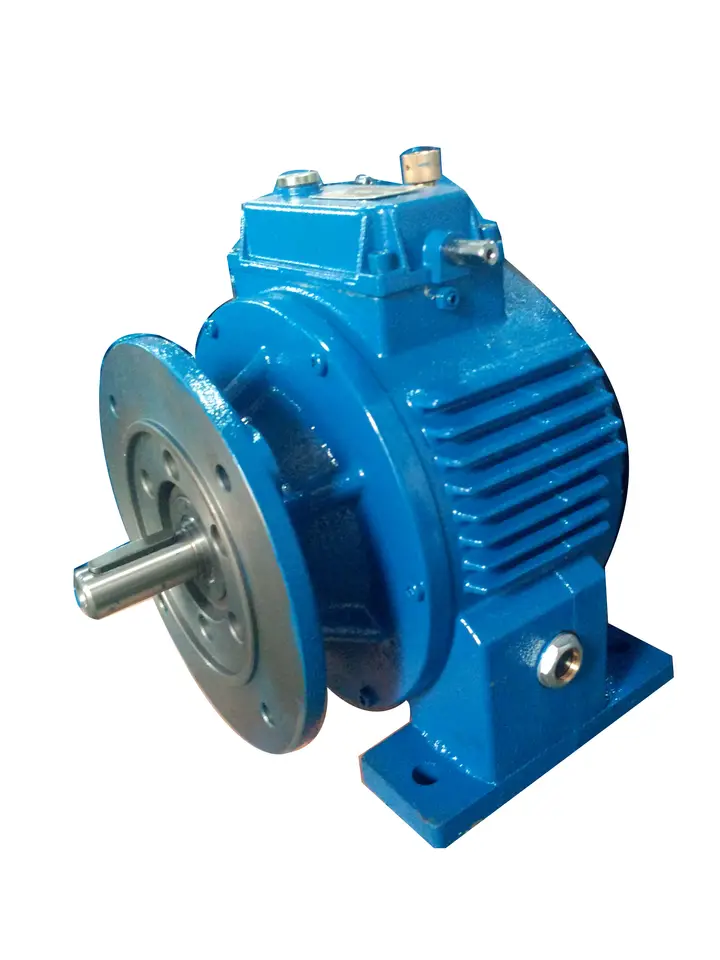

Product Description

1) High precision of speed regulating for speed variator,UD gear box: up to 0.5-1 round

2) Large speed-changing range: the speed ratio ranges from 1:1.4 to 1:7 freely

3) High intensity and long serving time

4) Convenient to regulate speed

5) Continuously workable, bidirectional working direction,smooth running,

stable, and quiet

6) Fully sealed and suitable to any environment

7) Compact structure, small size

8) High quality aluminum alloy die-cast, elegant shape, light weight and non-rusting

9) Good adaptability: can be combined with all kinds of reducers to achieve low

stepless speed changing

10) Input power: 0.18-7.5kW

| Power | Model | I | n2(r/min) | M2(NM) |

| 0.18kw | UDL0.18 | 1.6-8.2 | 880-170 | 1.5~3 |

| 0.37kw | UDL0.37 | 1.4-7 | 1000-200 | 3~6 |

| 0.55kw | UDL0.55 | 1.4-7 | 1000-200 | 4~8 |

| 0.75kw | UDL0.75 | 1.4-7 | 1000-200 | 6~12 |

| 1.1kw | UD1.1 | 1.4-7 | 1000-200 | 9~18 |

| 1.5kw | UD1.5 | 1.4-7 | 1000-200 | 12~24 |

| 2.2kw | UD2.2 | 1.4-7 | 1000-200 | 18~36 |

| 3kw | UD3 | 1.4-7 | 1000-200 | 24~48 |

| 4kw | UD4 | 1.4-7 | 1000-200 | 32-64 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Industry |

|---|---|

| Hardness: | Hardened |

| Type: | Worm and Wormwheel |

| Output Speed: | 1000-200r/M |

| Input Speed: | 1400rpm |

| Power: | 1.1kw-7.5kw |

| Customization: |

Available

| Customized Request |

|---|

How do variator gearboxes contribute to optimizing the efficiency of conveyor systems?

Variator gearboxes play a crucial role in optimizing the efficiency of conveyor systems. They offer several advantages that contribute to improved performance, energy efficiency, and overall productivity. Here’s how variator gearboxes help optimize the efficiency of conveyor systems:

- Variable Speed Control: Variator gearboxes enable precise and continuous adjustment of the conveyor’s speed. This variable speed control allows operators to match the conveyor’s speed to the specific requirements of the material being transported or the production process. By running the conveyor at the optimal speed, energy wastage is minimized, and the system operates more efficiently.

- Load Adaptability: Conveyor systems often handle varying loads or different types of materials. Variator gearboxes offer load adaptability, allowing the conveyor to adjust its speed and torque output based on the applied load. This adaptability ensures that the conveyor operates at the appropriate power level, minimizing energy waste during periods of low load or when handling lighter materials.

- Smooth Starting and Stopping: Variator gearboxes provide smooth acceleration and deceleration capabilities, allowing the conveyor to start and stop gradually. This feature reduces stress on the conveyor components, minimizes jerky movements, and prevents material spillage. Smooth starting and stopping also contribute to energy efficiency by reducing power surges and mechanical stress on the system.

- Optimized Power Transmission: Variator gearboxes are designed to optimize power transmission efficiency. They utilize efficient power transfer mechanisms, such as belts or chains, along with well-engineered pulley systems. These systems minimize power losses due to friction and slippage, ensuring that a greater percentage of input power is effectively delivered to the conveyor belt, reducing power consumption.

- Customizable Gear Ratios: Variator gearboxes offer a wide range of gear ratios that can be adjusted based on the specific conveyor requirements. By selecting the optimal gear ratio, the variator gearbox ensures efficient power transfer and reduced power losses. The customizable gear ratios allow the conveyor to operate at the most favorable speed and torque combination, maximizing energy efficiency.

- Integrated Control Systems: Variator gearboxes can be integrated with advanced control systems and automation technologies. These systems enable precise control over the conveyor’s speed, acceleration, and deceleration profiles. By implementing intelligent control algorithms, variator gearboxes can optimize the conveyor’s operation based on real-time production demands, minimizing power consumption and maximizing productivity.

- Maintenance and Serviceability: Variator gearboxes often offer ease of maintenance and serviceability features. They may incorporate features like quick belt tension adjustment mechanisms, easy access to components for inspection and maintenance, and built-in condition monitoring systems. These features simplify maintenance tasks, reduce downtime, and ensure that the gearbox operates at its peak efficiency.

By leveraging the variable speed control, load adaptability, smooth starting and stopping, optimized power transmission, customizable gear ratios, integrated control systems, and maintenance features, variator gearboxes contribute to the overall optimization of conveyor system efficiency. They enable energy-efficient operation, reduce power consumption, enhance material handling capabilities, and improve the productivity and reliability of conveyor systems in various industries.

How do variator gearboxes contribute to energy efficiency and reduced power consumption?

Variator gearboxes play a significant role in improving energy efficiency and reducing power consumption in various applications. They offer several advantages that contribute to these benefits. Here’s how variator gearboxes help achieve energy efficiency and lower power consumption:

Variable Speed Operation:

One of the primary ways variator gearboxes contribute to energy efficiency is by enabling variable speed operation. Unlike fixed-speed gearboxes, variator gearboxes allow for continuously adjustable speed ratios within a specific range. This feature allows the machinery or equipment to operate at the optimal speed for a given task or load. By running the system at the required speed rather than a fixed maximum speed, energy wastage due to unnecessary high-speed operation is minimized, resulting in energy savings.

Efficient Power Transmission:

Variator gearboxes are designed to optimize power transmission efficiency. They utilize efficient power transfer mechanisms, such as belts or chains, along with well-engineered pulley systems. These systems minimize power losses due to friction and slippage. Compared to other mechanical transmission systems, variator gearboxes can achieve higher overall transmission efficiency, ensuring that a greater percentage of input power is effectively delivered to the output, reducing power consumption.

Load-Adaptive Operation:

Variator gearboxes allow for load-adaptive operation, meaning they can adjust the output speed and torque according to the applied load. When the load requirements are low, the variator gearbox can reduce the speed and torque output, resulting in lower power consumption. This load-adaptive operation ensures that the machinery or equipment operates at the appropriate power level to meet the specific load demands, minimizing energy waste during periods of low load.

Optimized Gear Ratios:

Variator gearboxes offer a wide range of gear ratios that can be adjusted based on the specific application requirements. By selecting the optimal gear ratio, the variator gearbox allows for efficient power transfer and reduced power losses. The ability to customize the gear ratios ensures that the machinery or equipment can operate at the most favorable speed and torque combination, maximizing energy efficiency and minimizing power consumption.

Regenerative Braking:

Some variator gearboxes, particularly those used in hybrid or electric vehicle applications, incorporate regenerative braking systems. These systems harness the energy generated during braking or deceleration and convert it into electrical energy, which can be stored and reused. By recovering and reusing this energy, variator gearboxes contribute to overall energy efficiency and reduce the power consumption of the vehicle or system.

Control Systems and Automation:

Variator gearboxes can be integrated with advanced control systems and automation technologies. These systems enable precise control over speed, torque, and power output. By implementing intelligent control algorithms, variator gearboxes can optimize their operation based on real-time load conditions, further enhancing energy efficiency and reducing power consumption.

Overall, variator gearboxes offer variable speed operation, efficient power transmission, load-adaptive operation, optimized gear ratios, regenerative braking (in certain applications), and integration with control systems. These features and capabilities contribute to improved energy efficiency and reduced power consumption, making variator gearboxes a valuable choice for applications where energy savings are a priority.

Can you explain the different types of variator gearboxes and their functions?

There are several different types of variator gearboxes, each with its own design and function. Here are some of the common types:

- Belt-and-Pulley Variators: Belt-and-pulley variators, also known as variable speed drives or variable speed transmissions (VSTs), use a belt and a set of variable diameter pulleys to achieve speed variation. The pulleys can change their effective diameter by adjusting their position, allowing for continuous adjustment of the output speed. Belt-and-pulley variators are commonly used in applications such as vehicles, industrial machinery, and power transmission systems.

- Cone Variators: Cone variators, also called toroidal or traction drive variators, use a pair of conical disks or rollers to achieve speed variation. The conical elements have varying radii, and their contact point determines the output speed. As the cones move closer or farther apart, the effective radius changes, resulting in speed adjustment. Cone variators are often employed in applications where compact size, high torque capacity, and high efficiency are desired, such as in automotive transmissions and industrial power transmission systems.

- Disc Variators: Disc variators, also known as disc drives or disk-and-roll variators, use a set of interlocking discs and rollers to achieve speed variation. The discs have spiral grooves that guide the movement of the rollers. By adjusting the axial position of the rollers, the effective diameter of the variator changes, leading to speed control. Disc variators are commonly used in applications where high torque capacity and precise speed control are required, such as in heavy machinery, construction equipment, and marine propulsion systems.

- Hydrostatic Variators: Hydrostatic variators use hydraulic systems to achieve speed variation. They typically consist of a pump, a motor, and a control valve. The pump supplies hydraulic fluid under pressure, which drives the motor to generate rotational motion. By controlling the flow rate and pressure of the hydraulic fluid, the output speed can be adjusted. Hydrostatic variators are commonly used in applications that require high torque, precise control, and the ability to handle heavy loads, such as in construction machinery, agricultural equipment, and machine tools.

- Torque Converter Variators: Torque converter variators, also known as fluid couplings, use a fluid-filled chamber to transmit torque and achieve speed variation. They consist of an impeller, a turbine, and a stator. The impeller and turbine are connected to the input and output shafts, respectively, and the stator redirects the fluid flow. By altering the fluid flow characteristics, torque converter variators allow for speed control. They are commonly used in automotive automatic transmissions and heavy-duty industrial applications.

Each type of variator gearbox offers specific advantages and is suitable for different applications based on factors such as torque requirements, speed range, efficiency, compactness, and control options. The selection of the appropriate variator gearbox depends on the specific needs and constraints of the application at hand.

In summary, the different types of variator gearboxes include belt-and-pulley variators, cone variators, disc variators, hydrostatic variators, and torque converter variators. Each type has its own design and function, providing a range of options for achieving continuous and stepless speed variation in various mechanical systems.

editor by CX 2024-05-08