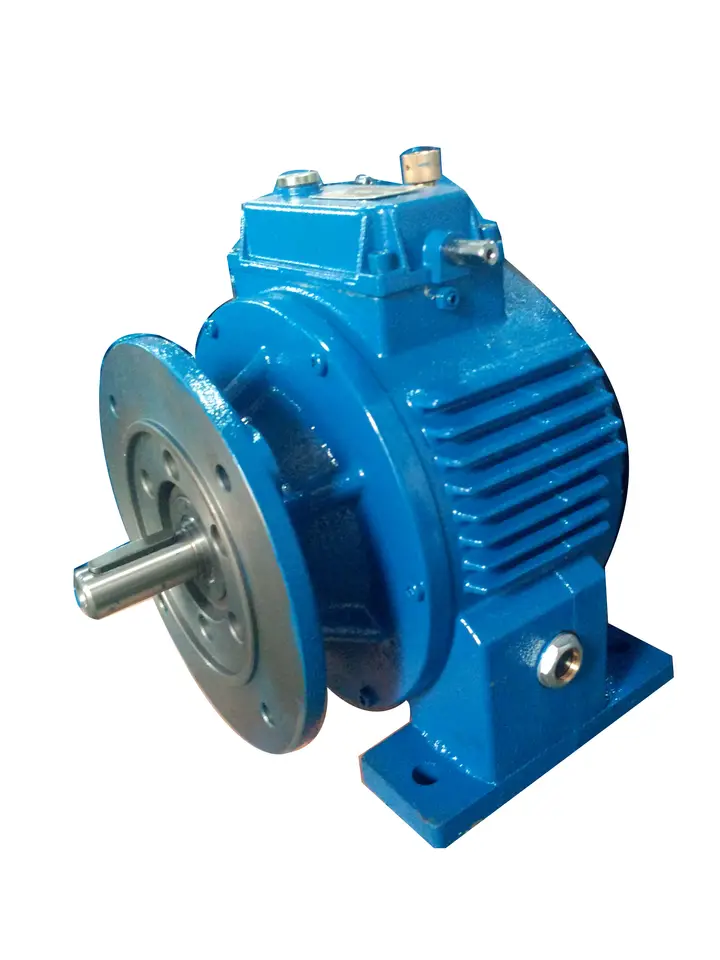

Product Description

Detailed Photos

Features of S series reducer

The same model can be equipped with motors of various powers. It is easy to realize the combination and connection between various models.

The transmission efficiency is high, and the single reducer efficiency is up to 96%. three

The transmission ratio is subdivided and the range is wide. The combined model can form a large transmission ratio and low output speed.

The installation forms are various, and can be installed with any foot, B5 flange or B4 flange. The foot mounting reducer has 2 machined foot mounting planes.

Helical gear and worm gear combination, compact structure, large reduction ratio.

Installation mode: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

Input mode: motor direct connection, motor belt connection or input shaft, connection flange input.

Average efficiency: reduction ratio 7.5-69.39 is 77%; 70.43-288 is 62%; The S/R combination is 57%.

S57 SF57 SA57 SAF57 S series helical worm gear box speed reducer 0.18kw 0.25kw 0.37kw 0.55kw 0.75kw 1.1kw 1.5kw 2.2kw 3kw, max. permissible torque up to 300Nm, transmission ratios from 10.78 to 196.21. Mounting mode: foot mounted, flange mounted, short flange mounted, torque arm mounted. Output shaft: CHINAMFG shaft, hollow shaft (with key, with shrink disc and with involute spline).

Product Parameters

Company Profile

Certifications

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How do variator gearboxes handle changes in speed while maintaining efficiency?

Variator gearboxes are designed to handle changes in speed while maintaining efficiency through their unique construction and control mechanisms. Here’s how variator gearboxes achieve efficient speed handling:

Continuous Adjustment:

Variator gearboxes offer continuous and stepless adjustment of the gear ratio or speed control mechanism. This feature allows for precise control of the output speed, enabling efficient handling of speed changes. By continuously adjusting the gear ratio, variator gearboxes can match the desired output speed while minimizing energy losses and maintaining overall efficiency.

Responsive Control Mechanisms:

Variator gearboxes incorporate control mechanisms that respond quickly to speed adjustment inputs. These control mechanisms can be mechanical, hydraulic, electronic, or a combination of these. When a change in speed is required, the control system activates and adjusts the variator mechanism to modify the gear ratio accordingly. The responsiveness of these control mechanisms ensures that speed changes can be executed promptly and efficiently.

Optimized Gear Design:

Variator gearboxes are engineered with optimized gear designs that minimize energy losses during speed changes. The gear profiles, tooth shapes, and gear ratios are carefully designed to reduce friction and improve the meshing efficiency between the gears. This optimization helps to maintain high power transmission efficiency even during speed adjustments, allowing the gearbox to handle changes in speed efficiently.

Stable Speed Maintenance:

Variator gearboxes are designed to maintain the selected speed setting with high stability. Once the desired speed is achieved, the gearbox is engineered to minimize speed variations due to external load changes or disturbances. This stability ensures that the output speed remains consistent, contributing to efficient speed handling. By minimizing speed fluctuations, variator gearboxes can prevent unnecessary energy losses and maintain overall efficiency.

Feedback and Control Systems:

Some variator gearboxes incorporate feedback and control systems that monitor the output speed and adjust the gear ratio or control parameters accordingly. These systems provide closed-loop control, constantly comparing the actual speed with the desired speed and making adjustments to maintain efficient speed handling. By continuously monitoring and fine-tuning the gear ratio, the gearbox can adapt to changing speed requirements while optimizing efficiency.

Wide Speed Range:

Variator gearboxes offer a wide range of achievable speeds, allowing for flexibility in speed handling. They can cover a broad spectrum of speed requirements by adjusting the gear ratio or other speed control mechanisms. This wide speed range enables efficient speed handling across different operating conditions and applications, ensuring that the gearbox can operate at its optimal efficiency throughout the speed range.

By incorporating continuous adjustment, responsive control mechanisms, optimized gear design, stable speed maintenance, feedback and control systems, and a wide speed range, variator gearboxes can handle changes in speed efficiently while maintaining high power transmission efficiency. These features make them well-suited for applications that require precise and efficient speed handling.

How do variator gearboxes contribute to energy efficiency and reduced power consumption?

Variator gearboxes play a significant role in improving energy efficiency and reducing power consumption in various applications. They offer several advantages that contribute to these benefits. Here’s how variator gearboxes help achieve energy efficiency and lower power consumption:

Variable Speed Operation:

One of the primary ways variator gearboxes contribute to energy efficiency is by enabling variable speed operation. Unlike fixed-speed gearboxes, variator gearboxes allow for continuously adjustable speed ratios within a specific range. This feature allows the machinery or equipment to operate at the optimal speed for a given task or load. By running the system at the required speed rather than a fixed maximum speed, energy wastage due to unnecessary high-speed operation is minimized, resulting in energy savings.

Efficient Power Transmission:

Variator gearboxes are designed to optimize power transmission efficiency. They utilize efficient power transfer mechanisms, such as belts or chains, along with well-engineered pulley systems. These systems minimize power losses due to friction and slippage. Compared to other mechanical transmission systems, variator gearboxes can achieve higher overall transmission efficiency, ensuring that a greater percentage of input power is effectively delivered to the output, reducing power consumption.

Load-Adaptive Operation:

Variator gearboxes allow for load-adaptive operation, meaning they can adjust the output speed and torque according to the applied load. When the load requirements are low, the variator gearbox can reduce the speed and torque output, resulting in lower power consumption. This load-adaptive operation ensures that the machinery or equipment operates at the appropriate power level to meet the specific load demands, minimizing energy waste during periods of low load.

Optimized Gear Ratios:

Variator gearboxes offer a wide range of gear ratios that can be adjusted based on the specific application requirements. By selecting the optimal gear ratio, the variator gearbox allows for efficient power transfer and reduced power losses. The ability to customize the gear ratios ensures that the machinery or equipment can operate at the most favorable speed and torque combination, maximizing energy efficiency and minimizing power consumption.

Regenerative Braking:

Some variator gearboxes, particularly those used in hybrid or electric vehicle applications, incorporate regenerative braking systems. These systems harness the energy generated during braking or deceleration and convert it into electrical energy, which can be stored and reused. By recovering and reusing this energy, variator gearboxes contribute to overall energy efficiency and reduce the power consumption of the vehicle or system.

Control Systems and Automation:

Variator gearboxes can be integrated with advanced control systems and automation technologies. These systems enable precise control over speed, torque, and power output. By implementing intelligent control algorithms, variator gearboxes can optimize their operation based on real-time load conditions, further enhancing energy efficiency and reducing power consumption.

Overall, variator gearboxes offer variable speed operation, efficient power transmission, load-adaptive operation, optimized gear ratios, regenerative braking (in certain applications), and integration with control systems. These features and capabilities contribute to improved energy efficiency and reduced power consumption, making variator gearboxes a valuable choice for applications where energy savings are a priority.

How do variator gearboxes contribute to continuously adjustable speed control?

Variator gearboxes play a significant role in providing continuously adjustable speed control in mechanical systems. They offer several key features and mechanisms that enable this capability:

- Stepless Speed Variation: Variator gearboxes allow for stepless and continuous adjustment of the output speed within a certain range. Unlike traditional gearboxes with fixed gear ratios, variators provide infinite possibilities for speed control. This feature enables precise and fine-tuned speed adjustments, allowing for optimal performance in various applications.

- Variable Diameter Pulleys: One common mechanism used in variator gearboxes is the variable diameter pulley system. This system consists of two pulleys connected by a belt. By adjusting the position of the pulleys, the effective diameter of the pulleys changes, altering the speed ratio between the input and output. This variable diameter pulley mechanism enables continuous adjustment of the output speed, providing the basis for continuously adjustable speed control.

- Smooth and Continuous Transitions: Variator gearboxes offer smooth and seamless transitions between different output speeds. As the pulley diameters are adjusted, the belt smoothly moves along the pulleys without sudden jumps or changes. This allows for precise and gradual speed control, ensuring smooth operation and minimizing any potential disruptions or vibrations in the mechanical system.

- Manual or Automatic Control: Variator gearboxes can be controlled manually or automatically, depending on the specific application. In manual systems, operators can adjust the pulley positions using mechanical or hydraulic mechanisms. Automatic systems, on the other hand, employ computer control or electronic control units (ECUs) to dynamically adjust the pulley positions based on various parameters such as speed, load, or user inputs. This flexibility in control options allows for efficient and convenient speed adjustments in different operating conditions.

- Wide Speed Range: Variator gearboxes typically offer a wide range of speed adjustment. The specific speed range depends on the design and capabilities of the gearbox. Some variators can achieve significant speed reductions or increases, allowing for versatile speed control in applications where a wide range of speeds is required.

The continuously adjustable speed control provided by variator gearboxes is beneficial in numerous applications. For example, in vehicles, variators are used in continuously variable transmissions (CVTs) to optimize engine performance and fuel efficiency. In industrial machinery, variators allow for precise control of rotational speeds in processes such as machining, material handling, and conveyor systems. Additionally, variators find applications in power transmission systems, where they enable efficient and flexible speed adjustments in generators, pumps, and other equipment.

In summary, variator gearboxes contribute to continuously adjustable speed control through their stepless speed variation, variable diameter pulley mechanisms, smooth transitions, manual or automatic control options, and wide speed range. These features make variator gearboxes valuable components in achieving precise and efficient speed control in various mechanical systems.

editor by CX 2024-03-27