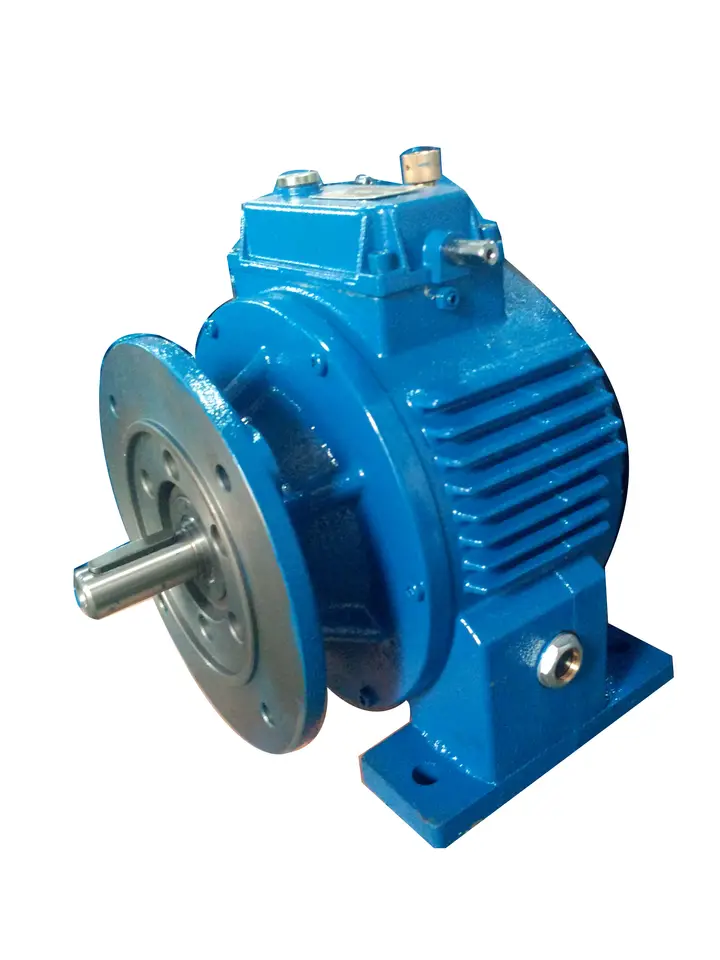

Product Description

manufacturer In-Line Udl Series B5 Reducer Gear Motor for plastic machine step-less speed variator UDL series planetary gearbox

UDL series stepless speed variators are widely used for foodstuffs, ceramics, packing, chemicals, pharmacy, lastics, paper-making, machine-tools, and all kinds of automatic lines, pipelines and assembly lines which need speed regulation.

1. High speed-regulating ,with precision: up to 0.5-1 rotation.

2. Large speed -changing range: The speed ratio ranges from 1:1.4 to 1:7 freely.

3. High in strength and long service life.

4. Convenient to regulate the speed.

5. Continuous in running, front-to-back in running direction, smooth in driving, stable transmission with lower noise.

6. Fully sealed and suitable for different working temperature

7. Compact structure and small volume.

8. Aluminium alloy and cast iron housing

9. Wide range of adaptation. UDL series stepless speed variators can be combined with all kinds of speed reducers,so as to achieve low stepless speed changing.

|

UD Model & Mark: |

UDL |

UD |

0.75 |

2 |

C |

5 |

B5 |

|

UDL 0.75 -2 -C -5 -B5 |

Planetary mechanical speed variator,aluminium casing |

Planetary mechanical speed variator, cast iron casing |

Motor power |

Two-staged gear matched; no mark stands for one-stage gear matched |

Code of one-staged or two-staged gear |

Reduction ratio for the matched gear |

Mounting position |

planetary gearbox

Planetary GearBoxes for Construction equipment

The gearbox is a vital mechanical part for construction machinery. Built to the highest quality standards, our planetary gearheads have won the recognition and trust of our customers. Our gear units can be used on various construction machines, such as tower cranes, crawler cranes, beam carriers, excavators, graders, concrete mixing plants, asphalt pavers, bridge machines, milling machines and other equipment. They are essential transmission components for bridge and road construction machines and all kinds of mining machines.

Application

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Soft Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Planetary |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What is a variator gearbox and how does it work in mechanical systems?

A variator gearbox, also known as a variable speed transmission, is a type of gearbox that allows for continuous and stepless variation of the output speed within a certain range. It is commonly used in mechanical systems where the output speed needs to be adjusted dynamically without fixed gear ratios. The variator gearbox achieves this by employing specific mechanisms such as belts, chains, or cones.

One common type of variator gearbox is the belt-and-pulley system. It consists of two variable-diameter pulleys connected by a belt. These pulleys can change their effective diameter by adjusting their position. The input pulley is connected to the power source, such as an engine or motor, while the output pulley is connected to the load. By varying the diameters of the pulleys, the speed ratio between the input and output can be continuously adjusted, allowing for a wide range of output speeds.

The variator gearbox works based on the principle of changing the effective radius of the pulleys. When the input pulley diameter increases or the output pulley diameter decreases, the belt is forced to ride higher on the pulley, resulting in a larger effective radius. This causes the output speed to decrease relative to the input speed. Conversely, when the input pulley diameter decreases or the output pulley diameter increases, the belt rides lower on the pulley, leading to a smaller effective radius and an increase in the output speed.

The variator gearbox can be controlled manually or automatically, depending on the application. In manual systems, the adjustment of the pulley diameters is done by the operator using mechanical or hydraulic mechanisms. In automatic systems, the adjustment is typically controlled by a computer or an electronic control unit (ECU) based on various parameters such as speed, load, or user inputs.

One of the key advantages of variator gearboxes is the ability to achieve smooth and stepless speed variation. Unlike traditional gearboxes with fixed gear ratios, variator gearboxes offer infinite possibilities for adjusting the output speed. This flexibility is particularly beneficial in applications where precise control of speed is required, such as in vehicles, industrial machinery, and power transmission systems.

However, it’s importan

Are there any limitations or drawbacks associated with variator gearbox systems?

Variator gearbox systems offer numerous advantages, but they also have certain limitations and drawbacks that should be considered. Here are some of the limitations and drawbacks associated with variator gearbox systems:

Limited Torque Capacity:

One limitation of variator gearboxes is their relatively limited torque capacity compared to some other types of gearboxes. Due to the design and construction of variator systems, they may not be suitable for applications that require extremely high torque transmission. In such cases, alternative gearbox systems with higher torque ratings may be more appropriate.

Restricted Speed Ratios:

Variator gearboxes typically have a limited range of achievable speed ratios compared to some other gearbox types. While they offer a continuous and stepless adjustment of the gear ratio, the maximum and minimum achievable ratios may be narrower compared to gearboxes with discrete gear steps. This limitation may restrict their suitability for certain applications that require extremely high or low speed ranges.

Complex Design and Maintenance:

Variator gearboxes can have a more complex design compared to conventional gearboxes. The presence of variable pulley systems, torque-sensing mechanisms, and control systems adds complexity to their construction. This complexity may require specialized knowledge and skills for maintenance and repairs. Additionally, the availability of spare parts and the cost of maintenance can be higher for variator gearboxes compared to simpler gearbox designs.

Potential for Heat Generation:

During operation, variator gearboxes can generate heat due to friction and mechanical losses. The continuous adjustment of the gear ratio and the interaction between the variable pulley system and the belt or chain can contribute to heat generation. Adequate cooling measures and lubrication systems may be necessary to dissipate heat effectively and prevent overheating, especially during prolonged operation at high speeds or under heavy loads.

Efficiency Losses:

While variator gearboxes can maintain reasonable power transmission efficiency, they may experience some efficiency losses compared to certain other gearbox types. The presence of additional components such as variable pulley systems, control mechanisms, and torque-sensing devices can introduce additional friction and mechanical losses, which can slightly reduce overall efficiency. However, advancements in technology and improved designs have mitigated this drawback to a significant extent in modern variator gearbox systems.

Cost Considerations:

Variator gearboxes can be more expensive compared to some traditional gearbox designs. The complexity of their construction, the need for precise control systems, and the use of specialized components can contribute to higher manufacturing and maintenance costs. Therefore, cost considerations should be taken into account when evaluating the feasibility of variator gearbox systems for specific applications.

Despite these limitations and drawbacks, variator gearbox systems continue to offer unique advantages in terms of continuous speed adjustment, efficient power transmission, and precise control. By carefully assessing the specific requirements of an application and considering the trade-offs, it is possible to determine whether a variator gearbox system is the most suitable choice.

t to note that variator gearboxes may have limitations in terms of torque capacity and efficiency compared to traditional fixed-ratio gearboxes. The power transmission efficiency of variator gearboxes can vary depending on the specific design and operating conditions.

In summary, a variator gearbox is a type of gearbox that allows for continuous and stepless variation of the output speed. It uses mechanisms such as belts, chains, or cones to adjust the effective diameter of the pulleys, enabling dynamic speed control in mechanical systems.

editor by CX 2023-08-30